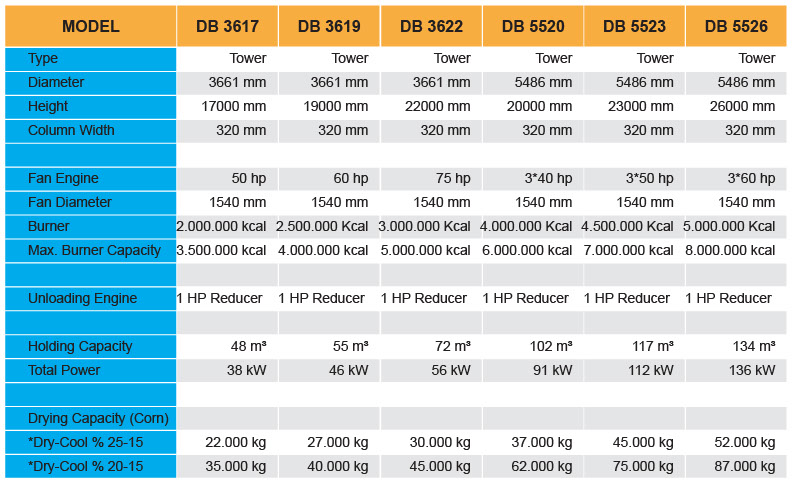

TOWER DRYERS

Technical Specifications

Safety

ADAKURUTMA® dryers are equipped with many safety features.

- Advanced slef-diagnostic check.

- Flame detection system

- Filling sensor.

- Air switch safety.

- Burning room safety.

- Product temperature safety.

- Outdoor temperature safety.

- Internal temperature safety.

- Motor overloads.

- Emergency stop butons.

SOME OF THE OUTSTANDING FEATURES

- Suction cooling is lowering energy consumption and provides fuel economy by using heat recovery system.

- Mixed Flow Industrial Fans. Highly efficient, quiet industrial fans provides years of trouble free operation.

- Automatic shut-off valves with modulating burner control.

- Grain exchangers equalize moisture and temperature in the grain column.

- Sealed cooling floor prevents particulate matter from entering the drying process for a cleaner dryer operation.

- Entry areas at the outer platforms allow for easy cleaning without restricting airflow.

- Easy access and service.

- Ample clearance under the dryer offers easy walk-through access and generous space for auxiliary equipment.

Tower dryers are designed for larger agricultural enterprises to meet their high volume grain drying needs at the contemporary standards. Tower dryers are the highest performance dryers with their ideal quality. The most important feature of them is high efficiency. Heat recovery and cooling without using additional options provide fuel economy and make them more advantageous than the module dryers.

ADAKURUTMA® tower dryers are made of high quality galvanized steel and outer sheets are made of perforated stainless steel which provides more longevity. Depending on the power and capacity, they are produced with between 1 and 3 blowers and their internal design creates a natural noise barrier and work quietly that provides additional advantages.

- Grain inlet does not require auger, reducing the number of moving parts.

- The filling part in the inner roof distributes the grain evenly which come from the grain entrance. This ensures complete and balanced filling of the grain columns

- Galvanized inner roof and support provides like 10 m³ of wet grain holding in the garner. The garner is totally sealed to retain particulate matter.

- Rotary switch controls the loading system so the dryer is kept full of grain all the time and the load system is turned on and off when needed.

- Outer perforated sheets are made of AISI 430 stainless steel. They greatly extends the life and appearance of the dryer. The screens utilize different size perforations to reduce emissions.

- Wide grain columns for longer air rotation and maximum efficiency.

- Heavy-duty overall construction results in an extra rigid structure on a minimum of ground space.

- All areas of the dryer are accessible through doors and floor hatches for easy cleaning and maintenance

- Inside and outside safety/service ladders, cages and catwalks provide safe and easy access to all areas of the dryer.

- ADAKURUTMA® grain exchange system helps to eliminate over drying and the balance the moisture content of dried grain in tower dryers. This unique system switches the grain from one side to another as it passes in the grain column. Grain exchangers are to equalize column moisture content and temperature of the grain column, greatly improving quality and efficiency.

- Walk-in heat section provides easy access for interior cleaning.

- Self-cleaning divider hopper separates the heating and cooling sections while preventing build-up of particulate matter.

- Internal mounting provides the added benefit of ultra-quite operation as the surrounding grain creates a natural noise barrier.

- Mixed Flow Industrial Fans. Highly efficient, quiet industrial fans provides years of trouble free operation.

- Heat recovery and suction cooling without using additional options saves energy and provide fuel economy.

- Walk-in cool section provides easy access to blowers and metering system.

- METERİNG DRİVE : variable speed ac motor and the reducer provides simple, trouble free operation of the dryers metering system.

- Unloading system uses paddles to evenly sweep grain to the center discharge hopper. Unloading floor made from stainless steel for long life.

- Gas Pipeline has 2 standard safety shut off valves .

- The power distribution box is galvanized and sealed. All electrical components are protected against transient voltage, spikes and surges. A main disconnect is standard for safe installation and service of the unit. Safety stop buttons on the outside of the control box allows for immediate shut-down in emergency situations.

- PLC control panel enables operator to run the system both automatically and manually in 3 languages. (Turkish-English-Russian) LCD touch screen monitor is easy to use. You can see the operating status of the augers, fans and heaters on the large , easy to read color touchscreen. Makes written and audible warnings in case of failure, thus malfunctions can be detected and sorted immediately.

- Manual control system is standard on all grain dryers. Allows manual control of all dryer functions with simple toggle switches. ADAKURUTMA® ’s manula control system is truly independent from the PLC system.

MIXED-FLOW FANS:

All ADAKURUTMA® dryers are optimized to provide just the right amount of airflow. Too little airflow adversely affects capacity, too much airflow adversely affects the efficiency. Depending on the dryer size 1 or 3 mix-flow blowers are used. Internally mounted, these in-line mixed-flow blowers operate at slow speeds, which means low noise levels, low electrical usage and results in long fan and motor life.

MAXIMUM PARTICULATE RETENTION:

ADAKURUTMA® tower dryers are designed to retain bees wings and particulate matter within the drying columns. The largest hole size on the exterior screening of the dryer is 2 mm diameter perforation. After the grain is turned, the perforation size drops to a diameter of 1,5 mm. solid non-perforated exterior sheets are used at the grain inverters and at the top and bottom of the grain columns to help ensure that particulates are not expelled from the dryer.

THE GRAIN EXCHANGER ADVANTAGE:

ADAKURUTMA® has developed grain exchange system to help eliminate over drying and the balance the moisture content of dried grain in tower dryers. This unique system switches the grain from one side to another as it passes in the grain column. Grain exchangers are to equalize column moisture content and temperature of the grain column, greatly improving quality and efficiency. This process maximizes grain quality while using less fuel and significantly reducing operating costs.

* The given drying capacities are for corn and could be changed depending on weather conditions, grain density, grain size etc.

ÇELİK KARDEŞLER LTD. ŞTİ.

Çökekler Mah.Ankara Cd. No: 487 Sakarya / TÜRKİYE Tel : +90 264 379 32 54 / info@adakurutma.com.tr