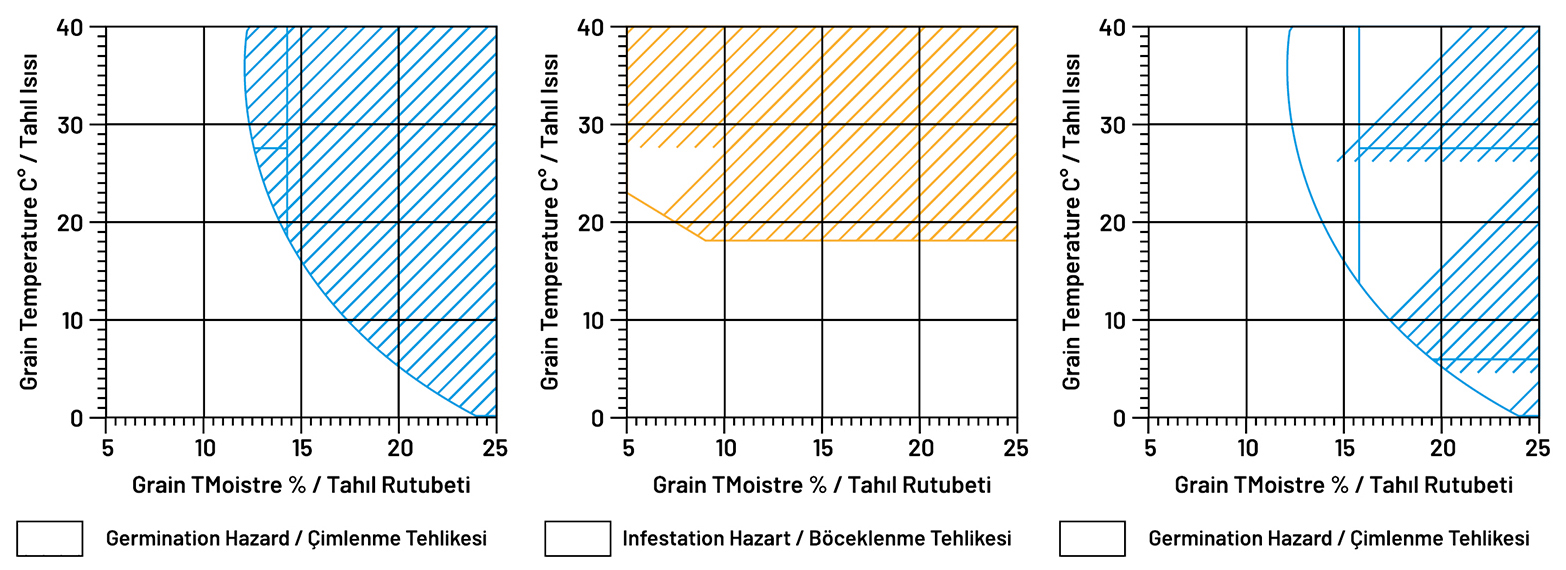

Monitoring and controlling the grain temperature in warehouse and silos has become compulsory to prevent losses. When the temperature reaches a certain value, the grain must be ventilated or transferred. If the grain temperature in the silo is not controlled; Mold, fungus, insect pests, biting or germination can occur rapidly. These occurrences cause degradation of grain in the whole silo and material loss . With the SiloSense “Silo Temperature Monitoring and Control System”, you can prevent products from being damaged so it prevent your losses!

It is designed to measure and process data regarding the

temperature and loading level of bulk materials in silos (such as grains -

wheat, corn, barley, rice; soybeans, animal feed, etc.). To monitor grain

temperature, digital sensors are placed at specific intervals inside the silo

based on its diameter, height, and capacity. These sensors are housed in casings

with high mechanical durability, compliant with food regulations. They can be

mounted from the roof or underneath the roof.

Color-coded reports quickly detect temperatures that are

hot, cold, or aggressively elevated from the previous reading. That allows

users to identify potential hotspots before they become a problem.